There isn't a bar or restaurant that doesn't use glass of some type to serve alcoholic beverages.

Glass is our trusty partner... the reliable vessel we hope to repeatedly serve and consistently deliver portion control for beverages... or so we think!

In many instances glass is more an act of faith, equivalent to the expectation that a grocer’s scale or petrol pump is accurate and the value we've paid for is what we’re really receiving.

The glass myth is not a question of glass importers or distributors deliberately misleading the hospitality industry, it's more about under-educating users. The outcome of the issues is that millions of restaurants and bars are unwittingly over-serving/ over pouring alcohol, collectively costing billions of $... yet no one says a word!

THE 3 FLAWS

- Act of Faith - The volumes you think you’re buying are approximates

- Factory marked plimsoll lines or volume level measures on beer and wine glassware are mainly guesses.

- That Oz and/or Metric conversions are rounded up or down.

Every mL or fraction of an Oz over served may cost little on a serve by serve basis yet multiplied tens of thousands of times weekly, monthly and yearly… it adds up!

ACT OF FAITH

Glass is made in large moulds, whereby thick molten glass is high pressured into a mould…during this process the glass will unevenly fill the mould’s internal cavity due to the manufacturing process. At times, there will be fairly large discrepancies in volumes representing 3-5% difference in the advertised volume designation attached to that glass!

To see the results of this issue line up 10-12 of the same volume glasses made by the same manufacturer… check bowl thicknesses at the bottom of each bowl, glass heights and glass diameters... see any differences?

Of course every production run will produce differences or tolerances within each batch and different production runs.

Whilst statistical averages from the manufacturer may indicate volume conformity over millions and millions of units, as we know from the “Claw of Averages”... the greater the number of glass units tested the lower the volume variations appear to be however, the small amount of glass units used in a bar or restaurant the difference in volume inaccuracy increases as the quantity of glass is comparably low.

PLIMSOLL LINES MARKINGS

A line measure means that a glass has a designation line, marked somewhere on the bowl of the glass to approximate where the desired or designated volume level is. Every market has different volume requirements and therefore the lines should be adjusted up or down, by the manufacturer however that may not always be the case.

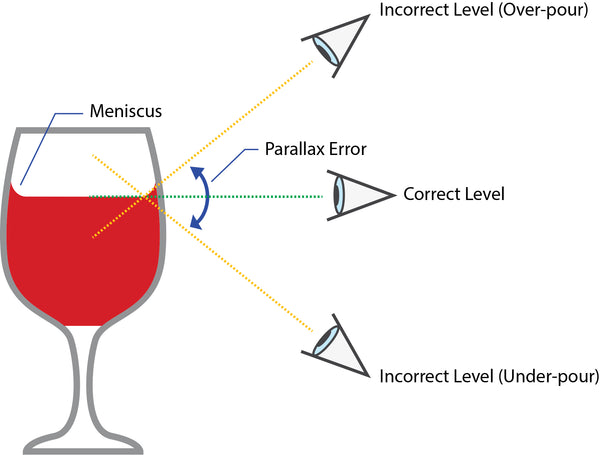

Above or below the line… Depending where a server stands in comparison to the glass, the line of the glass will appear differently (this is called parallax error)... stand at the same height as the glass and the volume line will probably correspond to the marked line. Look down on the glass or look up at the glass and the line appears different. When one pours into a glass slowly and deliberately a server can hit the line... but given the speed bars and restaurants run at how practical is that! Throw into the equation parallax error... then you’ve got a potential over-pouring issue!

VOLUME CONVERSIONS

Glass made in Europe is mainly designed to suit metric volumes, local jurisdiction... send the same glasses to the US or Canada the volumes are approximated into Oz, of course there is a difference between US and Canadian Oz’s.

The US use US Oz and in Canada, Imperial Oz’s... each with minor differences 1 Oz/3 0mL approx… in real terms US Ounce is 29.57mL and Canadian Ounce is 29.41mL. Glasses made in the US are made to US volume amounts, converted into mL’s.

So depending on which country the glass is made there will be differences in the actual advertised volumes due to metric/ounce conversions.

WHY IS UNDER EDUCATION GOOD FOR YOU?

When the customer (you) doesn’t understand the ramifications of inaccurate glasses to profitability and consistency on the bottom line, then distributor/manufacturers will never be held to account. They’ll continue doing what they’ve always done… you!

When customers demand better, at some point of time manufacturers will listen and do!

SO WHAT TO DO?

- Speak to your distributor.

- Measure and account for beer, wine and spirits shortages against POS records/inventory control, when you’re trying to find where possible discrepancies live, and inaccurate glassware may be the culprit.

- Buy an accurate measure or pour test kit to randomly check glassware volumes delivery by delivery for consistency… then decide what tolerance levels you’ll accept... reject glasses that do not conform or if you can increase your selling prices accordingly.

Oh yes one more thing!

Want to save a buck or two and buy cheaply made glasses... then consider this: what may be saved in upfront costs, may be lost quickly as these glasses tend to be made to a price not made for accuracy.

Ultimately you pay for what you get!